Digital Transformation in Logistics: Trends Reshaping the Industry

The logistics and supply chain industry has always been a complex, multi-layered network of processes that require precise coordination. However, the landscape has rapidly evolved driven by disruptive technologies, changing consumer expectations, and unpredictable global events. What was once a domain reliant on spreadsheets and physical paperwork is now undergoing an unprecedented shift toward digital innovation.

Digital transformation in logistics refers to the comprehensive integration of advanced technologies into every aspect of the supply chain from demand forecasting and warehouse management to freight monitoring and final-mile delivery. In 2025, this transformation is no longer optional; it is the key to competitiveness, resilience, and growth. For businesses aiming to streamline their operations, reduce costs, and respond more intelligently to market volatility, embracing this shift has become a strategic imperative.

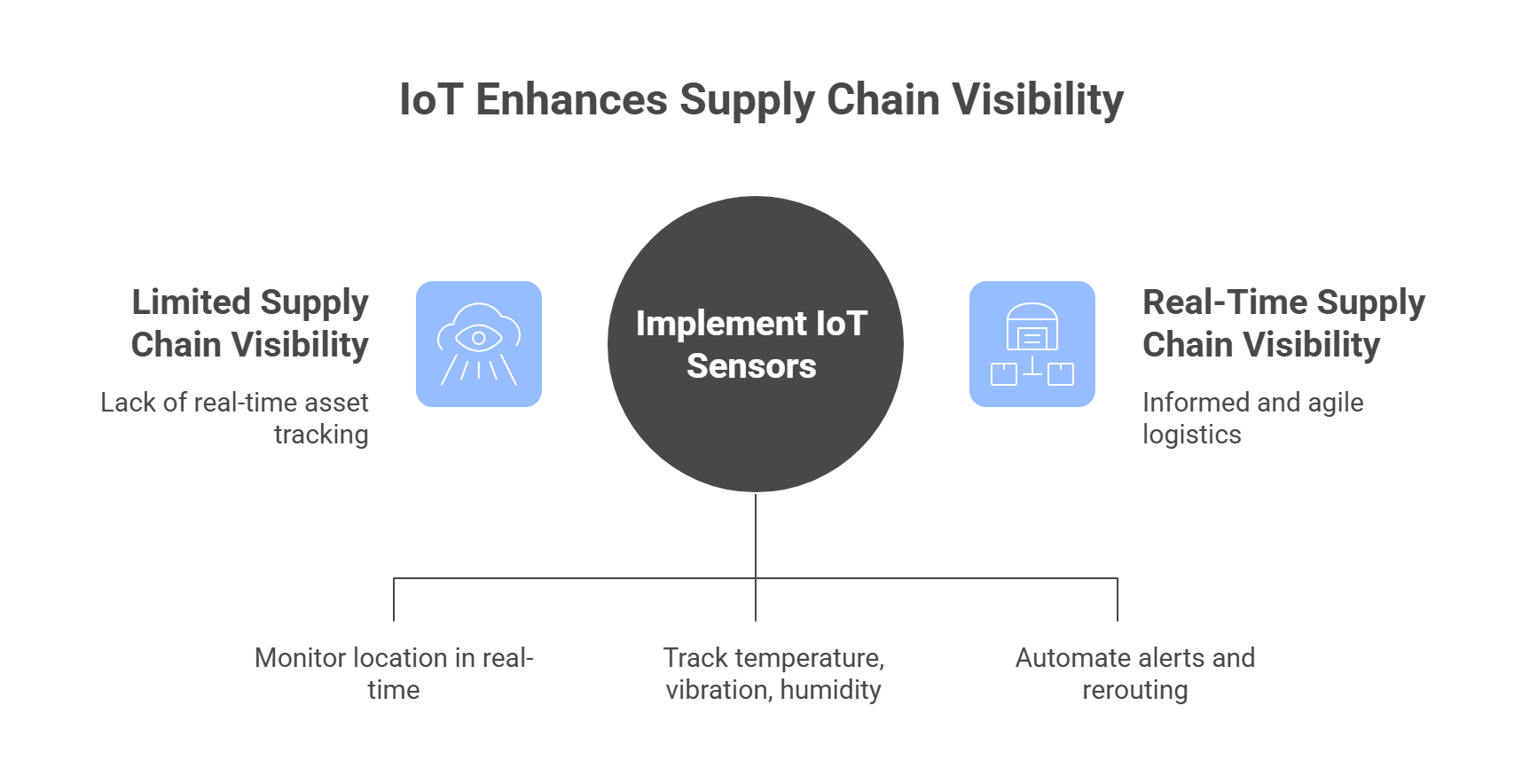

The Role of IoT in Real-Time Supply Chain Visibility

A cornerstone of modern logistics transformation is visibility knowing where assets are at any given time and what condition they are in. This has been made possible by the widespread adoption of the Internet of Things (IoT). Through connected sensors and smart devices, logistics teams can now track the movement, temperature, vibration, and humidity of goods in real time.

This capability not only enhances asset monitoring but also allows proactive decision-making. For instance, if a shipment of perishable goods experiences temperature deviation, the system can trigger an alert and automatically reroute the cargo to prevent spoilage. In a world where supply chains span continents and involve countless variables, real-time IoT-enabled visibility empowers logistics managers to stay informed and agile.

Leveraging Predictive Analytics to Anticipate Disruptions

Predictive analytics is emerging as a game-changer in logistics. By analyzing historical data and feeding it into AI models, businesses can identify trends and anticipate disruptions before they occur. Whether it’s predicting fuel cost fluctuations, planning for seasonal demand spikes, or detecting potential supplier delays, predictive analytics ensures logistics operations remain several steps ahead.

What sets predictive capabilities apart is their ability to turn raw data into actionable insights. Instead of reacting to issues after they happen, companies can simulate various scenarios and prepare response strategies in advance. This not only reduces downtime and losses but also increases overall supply chain resilience.

Intelligent Automation and the Future of Warehousing

Warehousing has undergone a profound transformation over the past decade. Today, automation is no longer confined to conveyor belts or barcode scanners. Robotics, AI-powered sorting systems, and autonomous mobile equipment have taken center stage in optimizing warehouse workflows.

Smart warehouses are now designed to function with minimal human intervention while ensuring maximum productivity. Robots assist in picking and packing, AI systems determine optimal storage configurations, and machine learning algorithms track inventory turnover in real time. These technologies not only reduce labor costs but also increase accuracy and speed, which are vital in meeting tight delivery schedules and managing complex product mixes.

Cloud-Based Infrastructure Enabling Scalable Logistics

The logistics industry has traditionally suffered from fragmented systems that inhibit collaboration and data sharing. Cloud-based platforms have resolved this challenge by offering unified systems that integrate inventory, transportation, customer orders, and supplier communications into a single digital interface.

With cloud technology, logistics organizations can access and update information from anywhere, fostering real-time coordination between internal teams and external partners. Moreover, cloud-based solutions provide the scalability needed to grow with business demands whether it’s expanding into new markets or managing increased volumes during peak seasons.

AI-Driven Transportation Optimization

One of the most resource-intensive aspects of logistics is transportation. In recent years, AI has been instrumental in reducing inefficiencies and improving routing decisions. Algorithms can now analyze thousands of data points including traffic patterns, fuel prices, and delivery time windows to determine the most cost-effective and reliable routes.

This optimization goes beyond route planning. AI systems also assist in determining the most suitable carriers, forecasting fuel needs, and even managing dynamic delivery pricing models based on urgency and demand. As a result, companies are experiencing reduced delivery times, lower operating costs, and improved customer satisfaction.

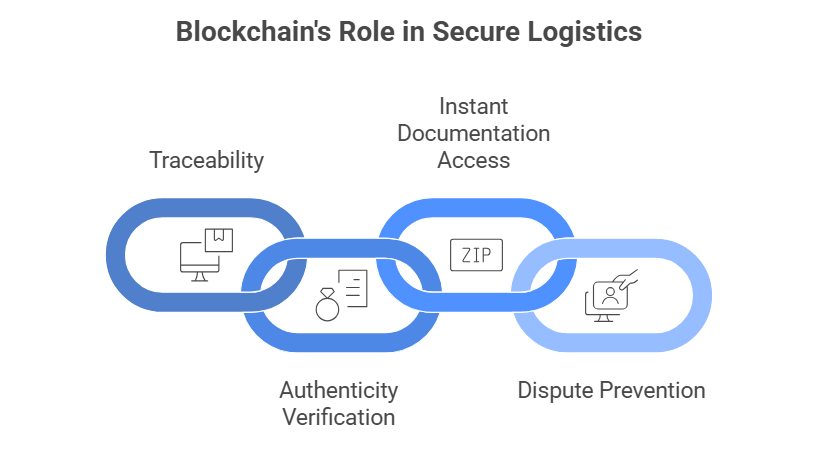

The Emergence of Blockchain in Secure Logistics

With complex global supply chains involving multiple intermediaries, ensuring trust and transparency is a growing challenge. Blockchain offers a solution by providing a tamper-proof, decentralized ledger of transactions.

When integrated into logistics workflows, blockchain development services enable:

- Traceability of goods across all nodes of the supply chain

- Authenticity verification for sensitive or high-value items

- Instant access to shipping and customs documentation

- Dispute prevention through verifiable records

While still maturing, blockchain is poised to become the backbone of secure and compliant supply chains in industries like pharmaceuticals, food, and electronics.

Sustainability Through Digital Innovation

Environmental sustainability has become a defining priority for logistics providers and their clients. With increasing scrutiny from regulators and consumers, companies are now leveraging digital tools to reduce their environmental impact.

Technologies such as AI and IoT contribute to greener operations by enabling fuel-efficient route planning, monitoring emissions, and optimizing packaging materials. Electric vehicles and eco-friendly warehousing practices are also becoming more widespread, often managed through cloud systems that track carbon footprints and sustainability metrics.

Digital transformation, therefore, is not only streamlining logistics operations but also helping organizations meet their environmental, social, and governance (ESG) goals.

Enhancing Customer Experience with Digital Logistics

- Personalized delivery options are now standard, allowing customers to select preferred time windows and locations.

- Real-time order tracking and notifications have replaced generic status updates, improving communication and reducing inquiries.

- Self-service returns, automated support bots, and mobile-enabled interfaces give customers control over post-purchase logistics.

- Businesses that integrate CRM data with logistics systems are delivering consistent, branded, and proactive customer experiences.

Final Thoughts

The logistics landscape is being rewritten by digital innovation. From predictive algorithms and IoT sensors to automation and cloud-native platforms, the race is on to build smarter, faster, and more resilient supply chains.

But digital transformation is not a one-time project it’s a mindset shift. It requires reimagining traditional logistics operations through the lens of data, speed, agility, and sustainability.

Companies embracing these changes not only reduce costs and delays but also deliver better customer experiences and unlock new business opportunities. App Maisters helps businesses make this shift, leveraging advanced technologies to optimize logistics operations and drive long-term growth.

FAQs

What does digital transformation in logistics involve?

Digital transformation in logistics includes adopting technologies like IoT, AI, and automation to streamline operations, reduce costs, and improve efficiency throughout the supply chain.

How does IoT help logistics companies?

IoT enables real-time tracking of goods, providing visibility into their location and condition. This allows for proactive management of shipments and reduces potential risks.

What are the benefits of predictive analytics in logistics?

Predictive analytics helps logistics companies anticipate disruptions, such as delays or demand changes, allowing them to take proactive actions and improve supply chain resilience.

How does AI improve warehouse and transportation management?

AI automates tasks in warehouses and optimizes transportation routes, improving efficiency, reducing costs, and ensuring faster deliveries.

How does blockchain enhance security in logistics?

Blockchain provides a secure, transparent way to track goods across the supply chain, preventing fraud and ensuring accurate and trustworthy documentation.